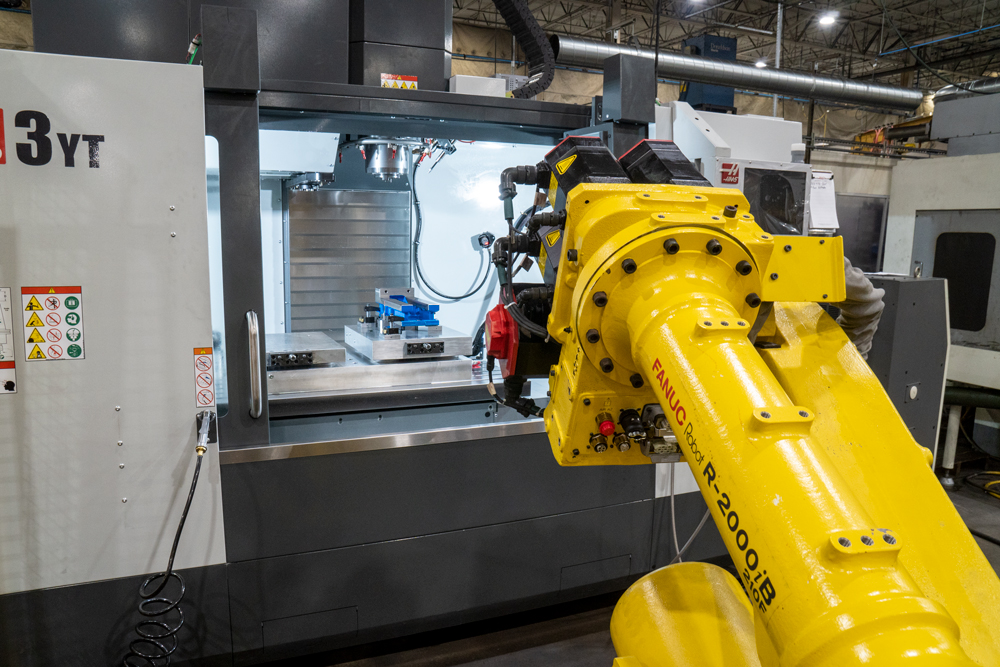

Haas VF-3YT vertical mill, Fanuc R-2000 iB 210F robot, hydraulic clamping system and Kurt DockLock pallet system are the perfect combination to automate large vise body machining.

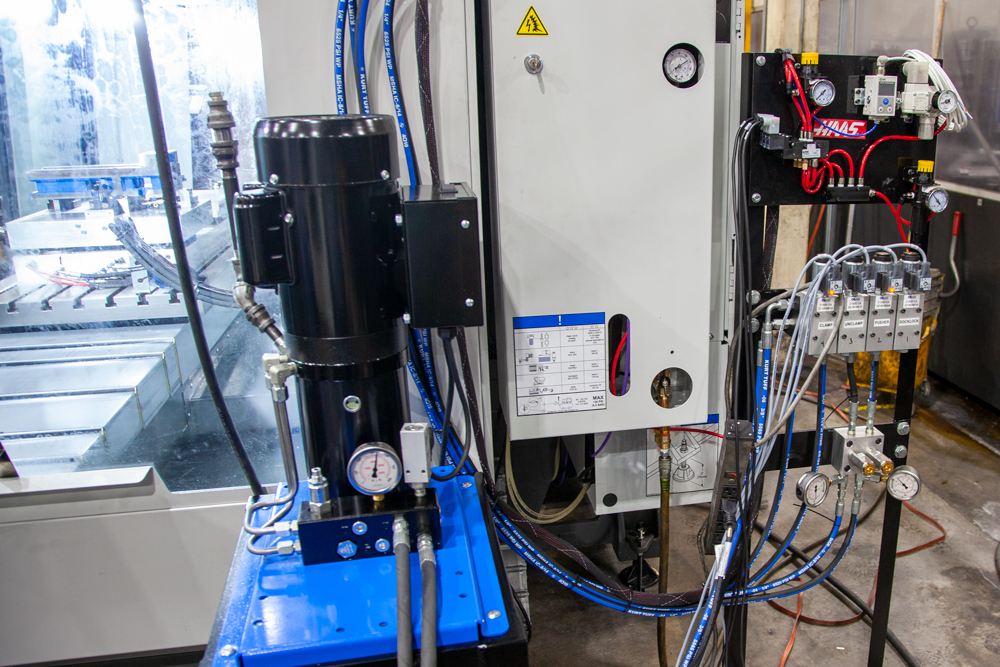

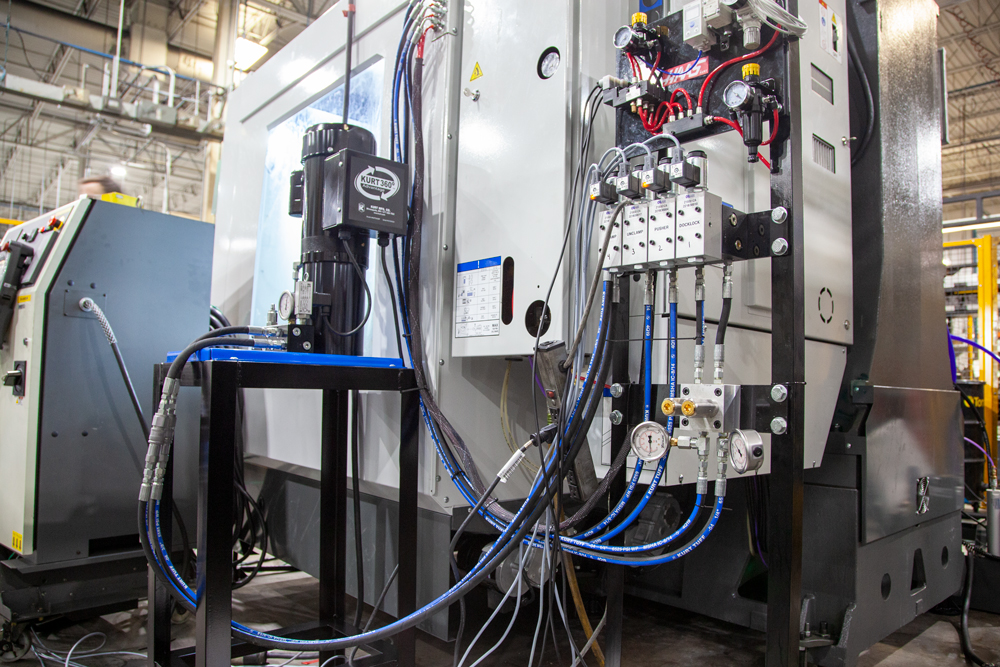

A new vise-production automation is now online in the Kurt Workholding division featuring end-to-end vise handling in addition to hydraulic Kurt DockLock receiver plates and a hydraulic swing-clamping system all connected to a Kurt KHP5000 double-acting hydraulic pump with Kurt Tuff braided hose and Kurt Solenoids. Vises are fed from heat treating to the machining cell with a conveyor belt system and loaded with a Fanuc robot.

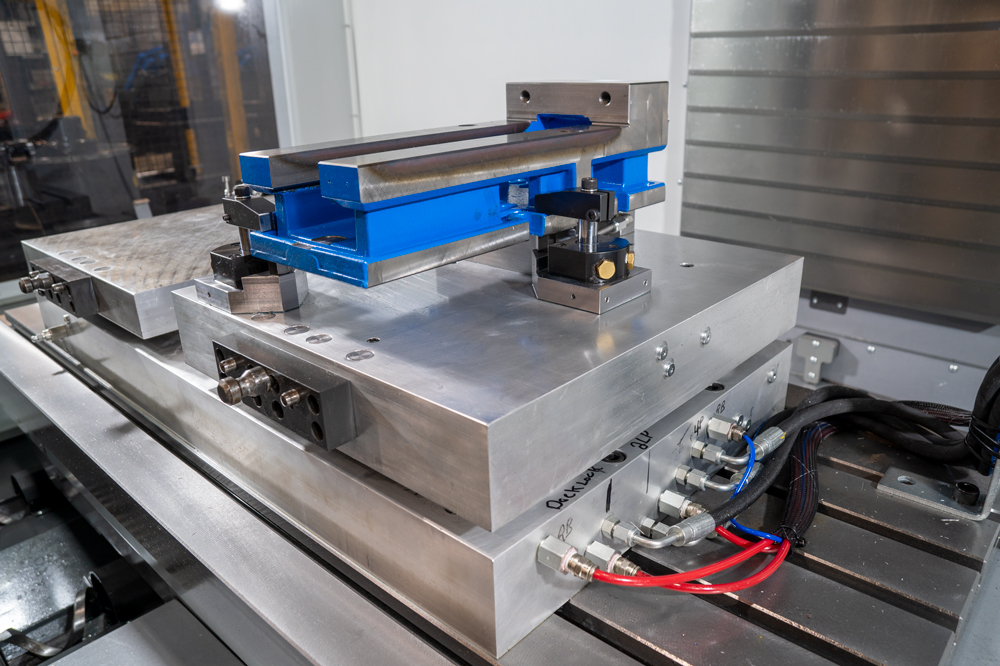

During the manufacturing process, vise bodies are robotically positioned in the machine and held tight with hydraulically controlled clamps. The Kurt DockLock pallet system allows multiple vise body sizes to run on the Haas VMC without operator setup changes. A simple robotic pallet change loads a new clamping configuration. The system can be programmed to produce a set quantity of individual vise models from two different conveyer belt feeds. This enables small runs of select vise bodies and helps Kurt keep up with demand on our varied product lineup while maintaining smart inventory levels in the warehouse.

Click video below to see the automation in action

Production improvements aren’t the only benefit of automations like the Haas cell. Safety improvements are also realized when large-part handling can be minimized.

“Automating vise-body loading and unloading and vise-machining processes has really accelerated production with lights-out machining capabilities,” Jeff Lenz, Executive Vice President, Proprietary Products, Kurt Manufacturing. “The added benefit is a reduction in employee over-use related injuries with a savings of approximately 100,000 pounds of lifting per year.”

Kurt Manufacturing’s multi-division structure creates synergy with shared services and product lines that work across divisions. Using proprietary Kurt products like, Kurt Hydraulics Tuff Hose and couplings, KHP5000 hydraulic pump and the associated solenoids and control systems not only demonstrate the quality of Kurt products in the field, but also save money and downtime for automated cells running in multiple Kurt facilities.“We count on Kurt Tuff hose and Kurt hydraulic couplings on our custom applications,” said Chuck Milam, Kurt Custom Engineered Workholding Sales Engineer. “We’ve had them up to 5,000 pounds of pressure easily when we 24-hour test our custom engineered workholding for quality assurance before sending it out to a customer.

Learn more about Kurt’s new DX8 vise lineup –>