Kurt KurtSPC Premium – d1

Part No. d1

$1,195.00

KurtSPC Premium statistical process control software allows you to collect data from most devices, and provide it at one location optimizing your manufacturing

Description

Description

Statistical Process Control Software

Statistical process control (SPC) is used to monitor and control a process to ensure that this process operates at its full potential. At full potential, a manufacturing process is capable of creating as much conforming product as possible with a minimum of waste. KurtSPC Premium statistical process control software is a simple to configure, easy to use solution for process optimization.

KurtSPC Premium software features user definable collection fields, error codes, and graphical or text operator instructions. It supports voice and video, customized screens and reports, machine tool controls, and automated gauging. The software also supports almost all types of gages and metrology tools, networking, and Kurt’s unique and powerful Event/Actions.

In short, KurtSPC Premium statistical process control software will allow you to collect data from almost any device, provide that data to you at one location in real time and in a meaningful way, allowing you to optimize your manufacturing processes.

What Can Statistical Process Control Software Do For You?

Manage Your Processes

- Security—To manage a process, it is necessary to control how it is configured. Detailed security options built into KurtSPC Premium give you that control.

- Organize—KurtSPC Premium statistical process control software allows you to organize your manufacturing and quality control configurations so that you can better manage your processes.

- Collect—The KurtSPC system allows you to interface to almost any device so that you can instrument your processes and collect important data in real time.

Standardize & Control Your Data Collection Process

- Network—Standardize data collection configuration, standardize reporting…the KurtSPC Premium network system allows process components to be shared with devices throughout your plant.

- Control—Controlling the data collection process helps improve the collected data’s accuracy. KurtSPC Premium statistical process control software allows you to create standard user interfaces, collection processes, and machine interfaces to help eliminate user error.

- Automate—Control all of your hardware from one system. KurtSPC Premium and KurtUSB I/O modules can act as a smart PLC, providing a clean way to automate your manufacturing hardware or collection process.

Improve Your Statistical Process Control

- Analyze—Use SPC, run tests, and create reports. Use KurtSPC Premium’s tools and intuitive displays to view your processes in new ways.

- Understand—When you have a standardized process for real time data collection, you are able to compare your data over time and from one location to the next. KurtSPC Premium statistical process control software helps you understand and improve your processes.

- Communicate—No matter how good or how timely your information is, it doesn’t help if you can’t communicate it to the people who need to know. KurtSPC Premium software provides messaging, alerts, reports, graphics, and controls to send your data where it needs to be, when it needs to be there.

Optimize Your Processes

- Feedback—Use the information you collect to optimize your processes. Make process changes and track them to assess how those changes have affected the process. Using that information can help make better, more effective process changes in the future.

- Continuous Improvement—Create a plan to standardize your process improvement methods. Let KurtSPC Premium statistical process control software help maintain your plan and control the changes needed to make it work.

Additional Information

- Windows XP to 7.0 Compatible

- Runs on both 32-bit and 64-bit operating systems

- Real time variables and attribute charting

- Spreadsheet, light column, and digital data entry

- Customizable screens and reports

- Provides advanced statistical analysis

- Direct gauge interface from virtually any source

- Event/actions, alarms, and assignable cause actions

- Multi-level security access and screen lock-out

- PC-based part print, photo, or CAD drawing displayed with features, video, and sound

- Control checks, error codes, and text tagging

- Closed-loop machine tool control and I/O support

- TCP, IP, IPX/SPX network supported

To learn more about KurtSPC Premium statistical process control software and how it can improve your manufacturing processes, contact Kurt Engineered Systems today.

|

|

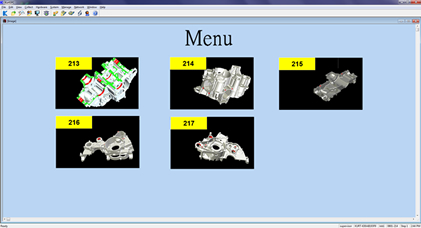

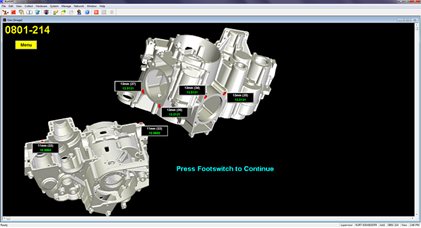

| Parts are selected for measurement by pressing the yellow button next to the part image. | The six features of the selected part are measured by hand tools in sequence and a summary screen showing the results of all features measured is displayed once all features of the part has been measured. |

|

|

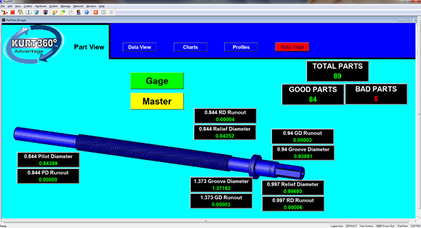

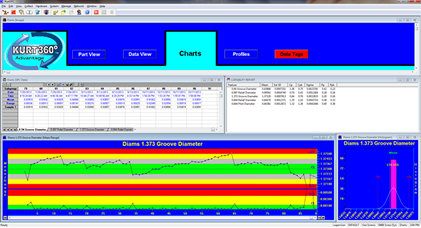

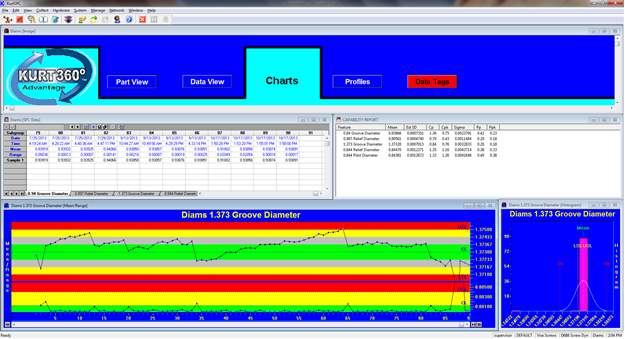

| All features of the screw are measured simultaneously with a fixture gage and the measurements of the screw are displayed once gaging is completed. | This screen shows the historical data collected as a trend chart, a histogram and as a data spreadsheet. A Process capability Report shows the process capability of all features being measured. |

|

|

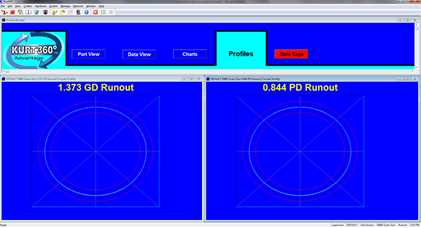

| This screen shows the radial profile of two of the features being measured. |

Please contact Kurt Gaging at 877-226-7823 to order a copy of the software.

Reviews

Reviews

You must be logged in to post a review.

There are no reviews yet.