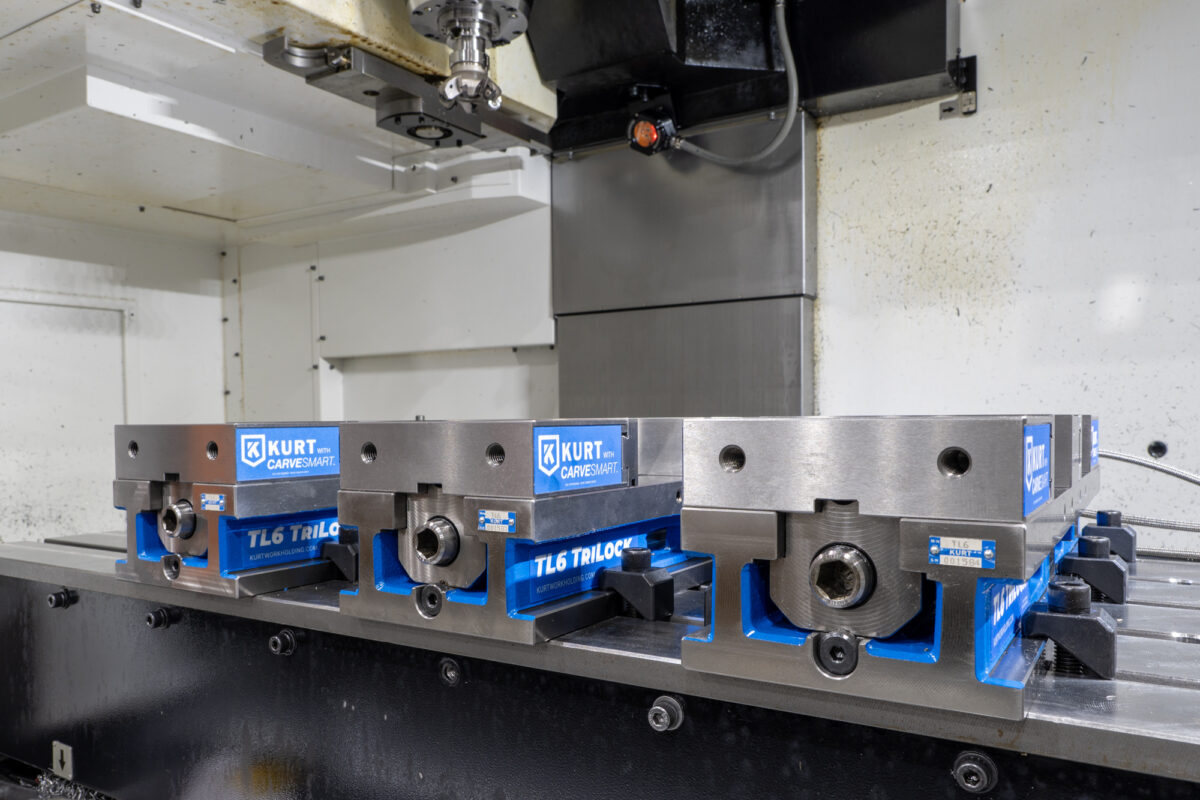

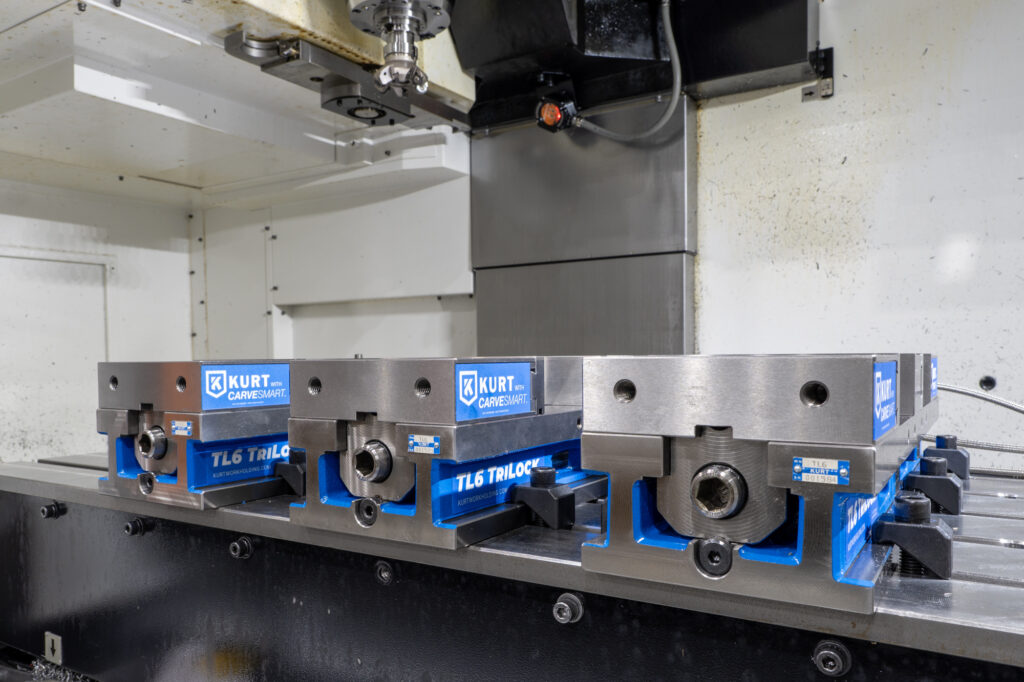

A trio of new TL6HCS hydraulic vises anchor this clever automation system—maximizing the potential of a vertical machining center.

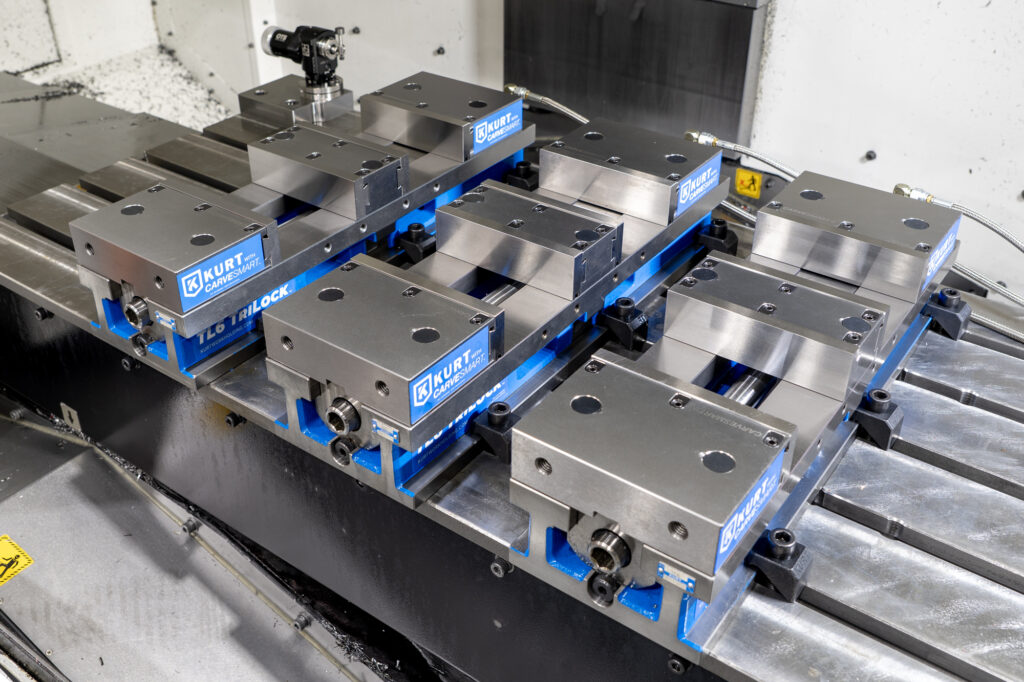

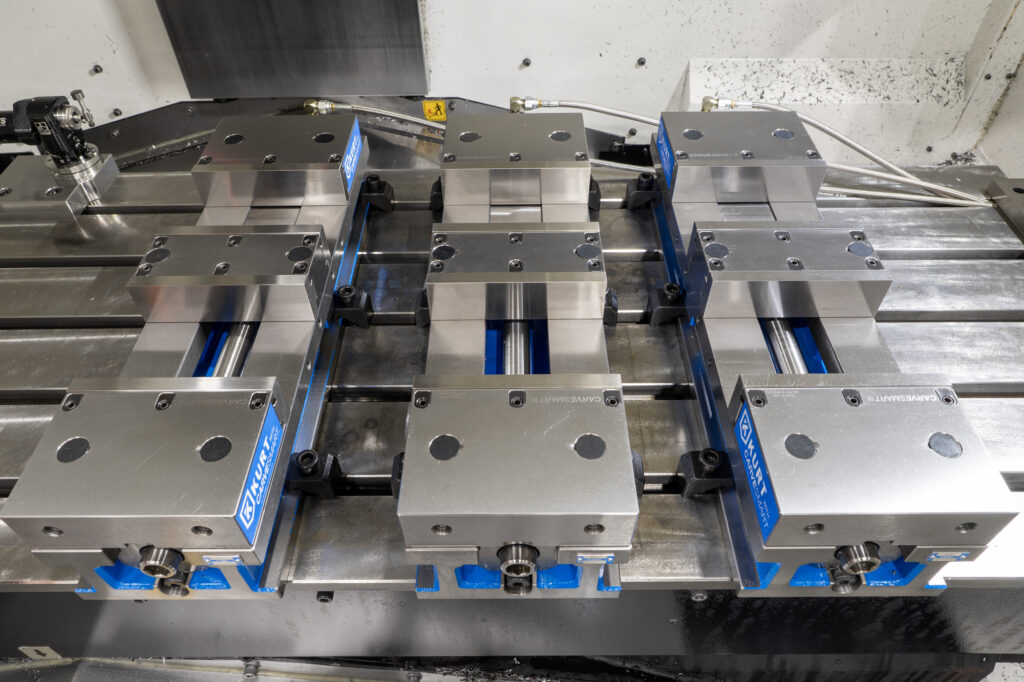

Our custom workholding team was recently approached by a customer based in Wichita, KS, who wanted to streamline production on Haas VF4SS machines. The part-holding requirements and budget for the project pointed our engineering team toward a flexible, high-density hydraulic vise automation solution. Part sizes and materials for this project will vary greatly—machining parts from both steel and plastic. Some parts will be as large as 45-inches long and require all three TriLock vises—configured as large single-station—to clamp a single part. Other parts will be small enough to clamp in a high-density workholding scenario as individual parts in each of the six jaw sets in a standard double-station TriLock configuration.

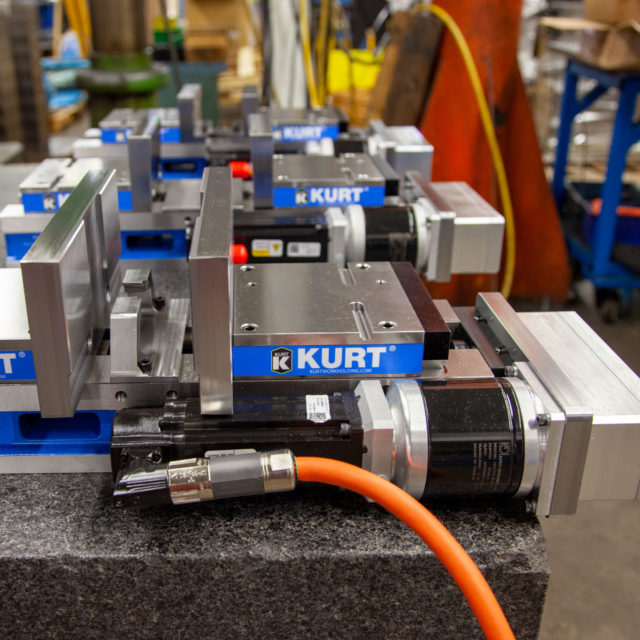

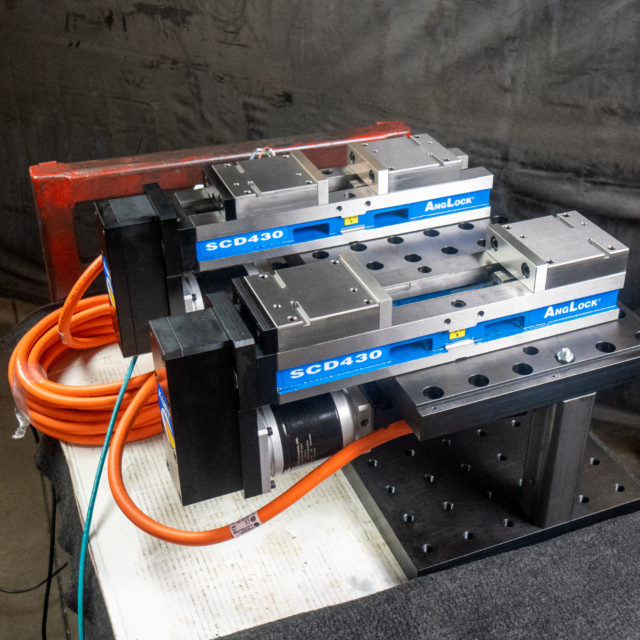

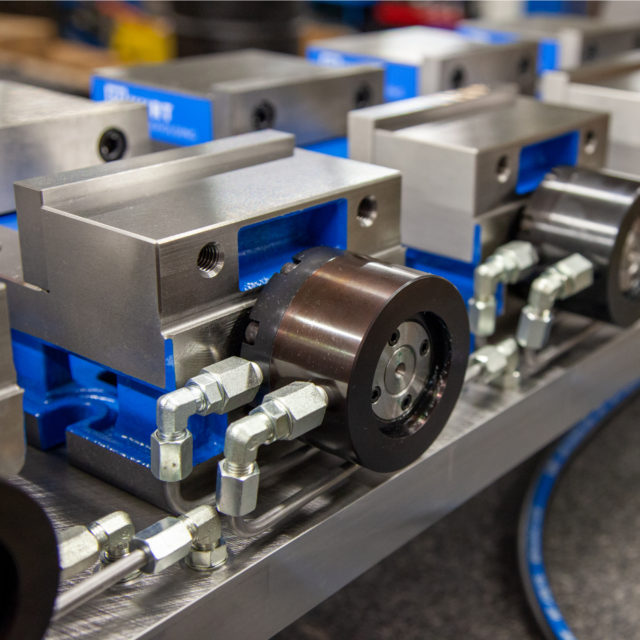

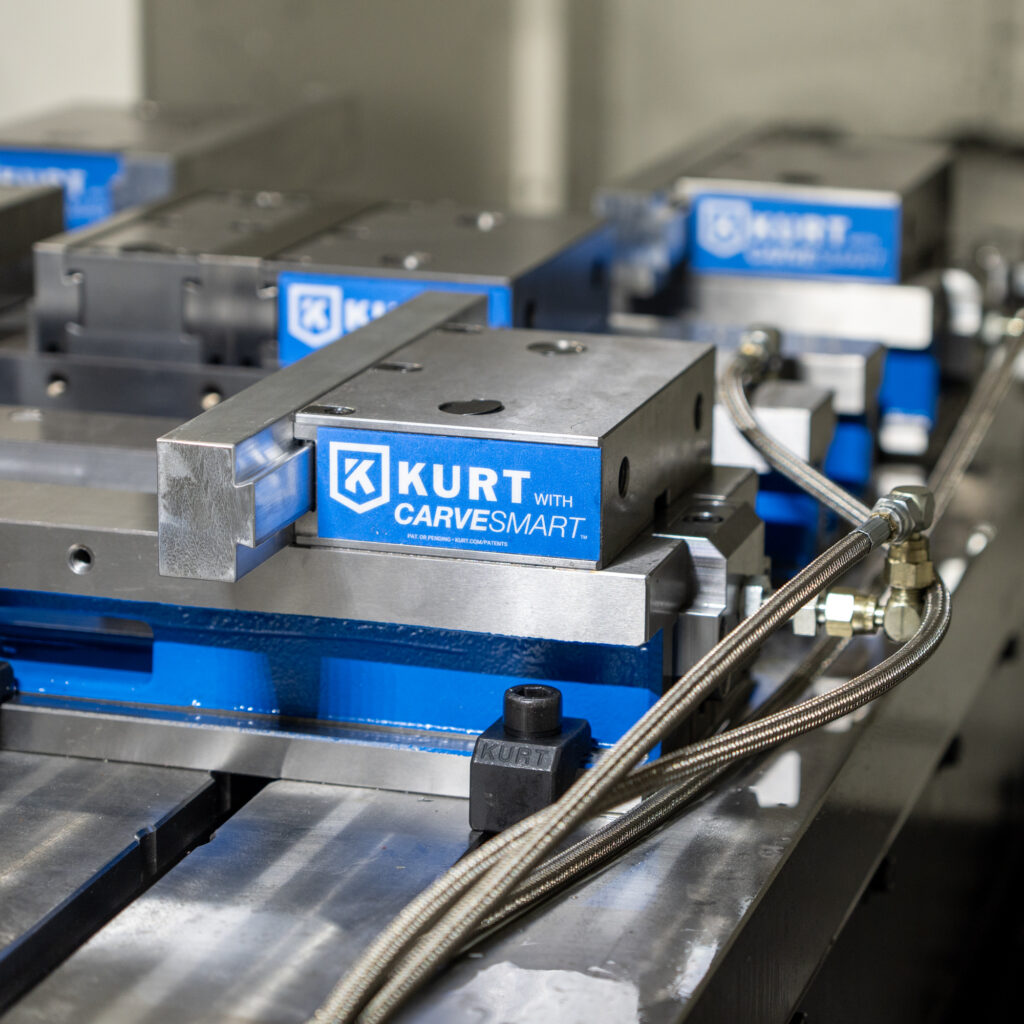

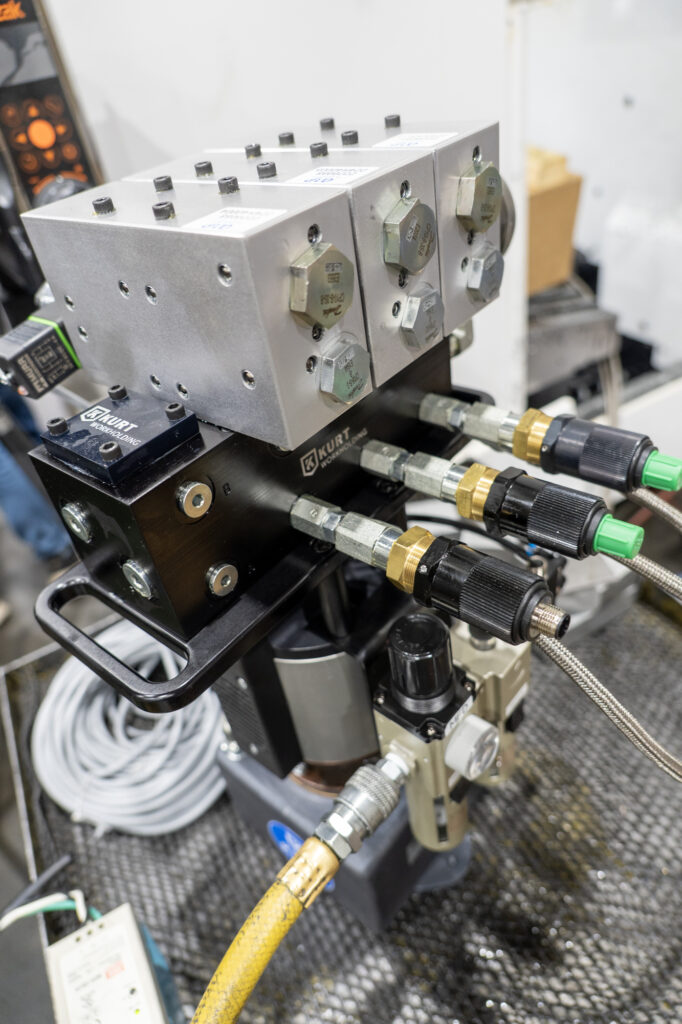

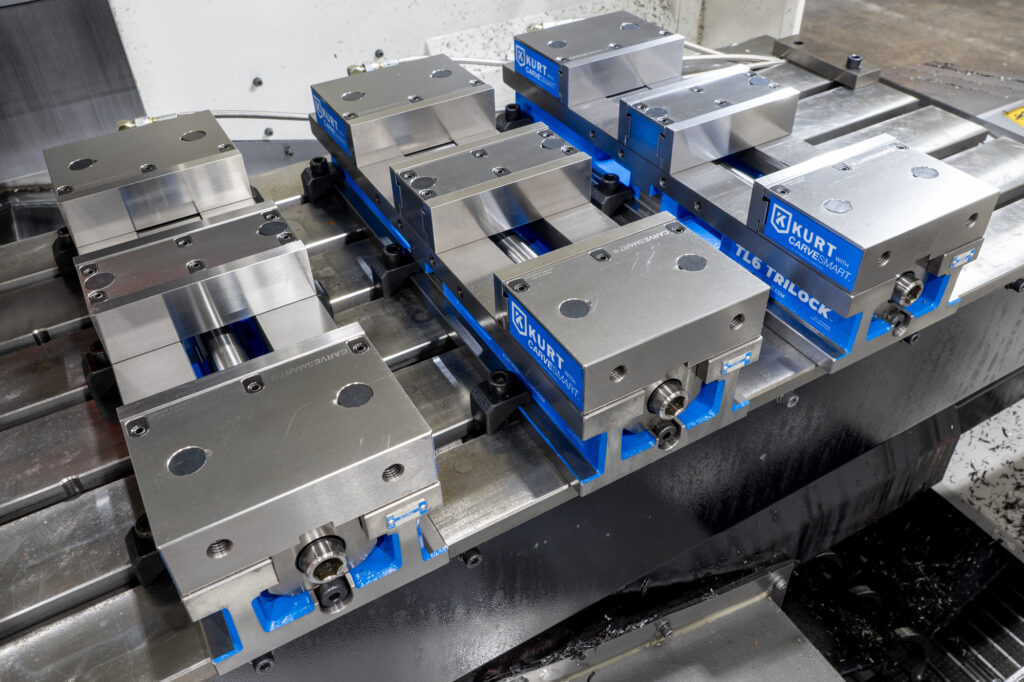

Our solution, shown here, incorporates a trio of 6-inch Hydraulic TriLock Vises with CarveSmart jaws, a Kurt KHP3T hydraulic pump and a custom control system. The pump and control system are a mix of custom and off-the-shelf products. Added solenoids, manifolds and electronics elevate the standard Kurt KHP3T hydraulic pump into an automation workhorse capable of controlling multiple vises. The TL6CSH TriLock vises are opened and closed remotely with an operator control box and a master foot switch. The three switches on the box each control one of the vises and allow individual vises to be actuated independently. The foot switch can then open and shut whichever vises have been activated at the 3-way control box.

The TriLock Design Maximizes Flexibility

The TriLock 3-in-1 design allows each of the individual vises to hold parts of varying sizes in three vise configurations including a standard double-station, single-station and large single-station vise. The three vises can also be set up to share a common jaw in any of the four sets of jaw openings as shown in the video. CarveSmart quick-change dovetailed jaws are used on each of the vises to maximize part-holding and material flexibility while minimizing setup and changeover times. The three-vise set up can be changed over in under 10 minutes from holding individual parts in six separate jaw sets to holding a single massive part in all three vises at once.

The TL6HCS TriLock Hydraulic Vise with CarveSmart Jaws is one of our newest models and will be available as a standard Kurt Workholding product in Winter 2025. Learn more here →

If you’re interested in applying a similar automation system to a custom engineered workholding application or learning how we can streamline an automated workflow, we’d love to help you out. We can build virtually anything imaginable.

Send us some project details and we’ll get back to you with the solution that’s right for your budget and your application.